Maximizing Efficiency in Business with Compressed Air Water Pumps

In today's fast-paced industrial landscape, the need for compressed air water pumps has escalated significantly. Companies across various sectors, including auto repair, farm equipment repair, and structural engineering, are leveraging these advanced tools to enhance productivity, reduce downtime, and improve overall efficiency.

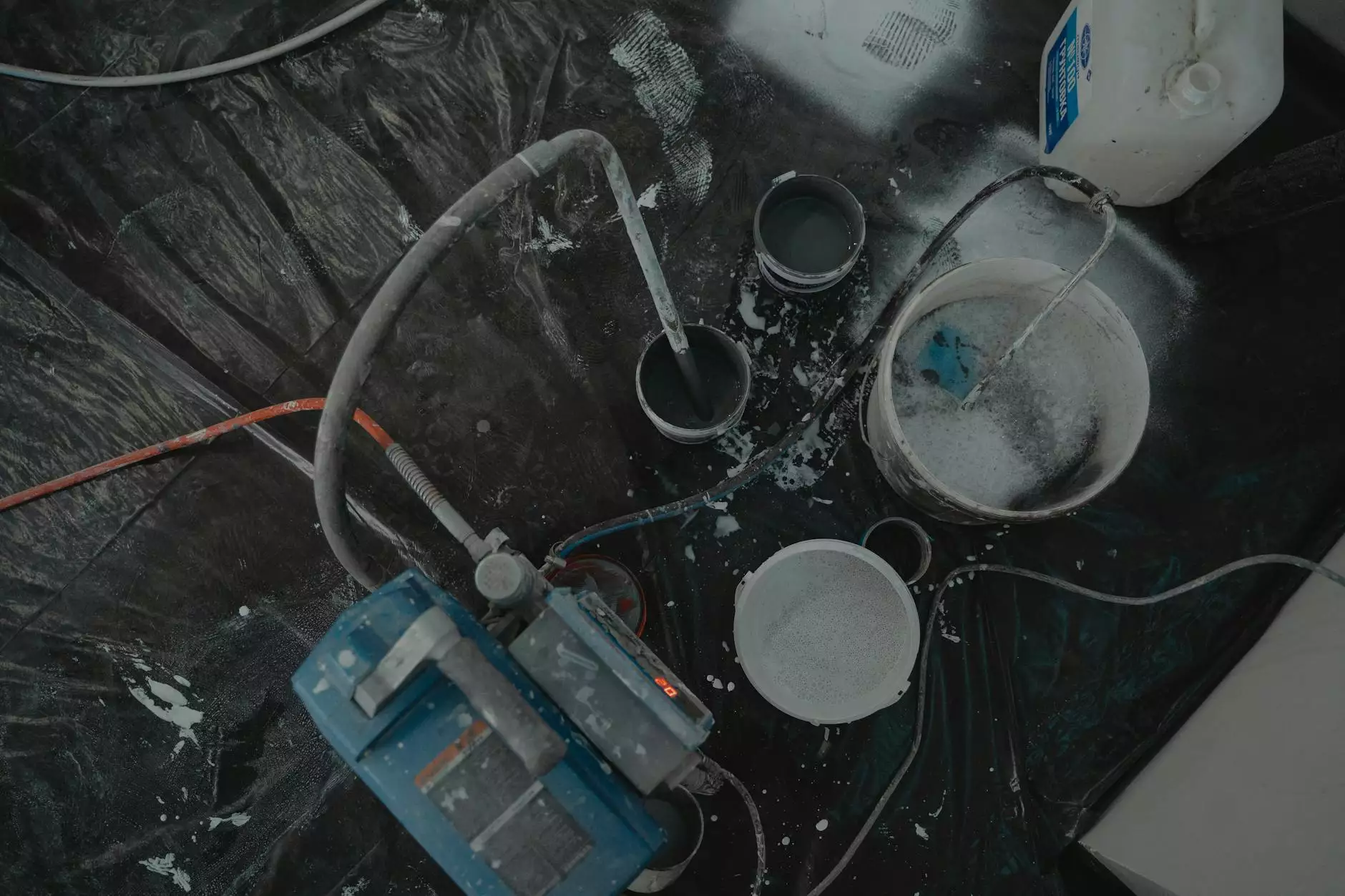

Understanding Compressed Air Water Pumps

A compressed air water pump utilizes compressed air to move water or other fluids, making it an essential tool in numerous applications. These pumps offer a range of advantages, including:

- Efficiency: These pumps operate quickly and are capable of moving large volumes of fluid in a short amount of time.

- Reliability: Compressed air pumps are typically more reliable than traditional electric pumps, as they are less prone to electrical failure and can operate in wet or hazardous environments.

- Eco-Friendly: Many models are designed to be energy-efficient, reducing your carbon footprint compared to standard pumps.

- Versatility: Suitable for various applications in auto repair, agriculture, and construction, making them a valuable asset in any workshop or field operation.

Applications of Compressed Air Water Pumps in Business

Companies like Michael Smith Engineers utilize compressed air water pumps across different sectors effectively. Below, we’ll explore specific applications within auto repair, farm equipment repair, and structural engineering:

1. Auto Repair

In the auto repair industry, time is of the essence. Mechanics require efficient tools to streamline their workflow. Compressed air water pumps are beneficial in several ways:

- Fluid Transfer: Quickly transferring fluids such as brake fluid, coolant, or oil enhances repair times.

- Cleaning: High-pressure water streams can help in cleaning engine parts and removing grime.

- Testing: These pumps are useful for testing cooling systems and checking for leaks in vehicles.

2. Farm Equipment Repair

Farm operations demand robust tools capable of handling tough conditions. Compressed air water pumps facilitate various tasks:

- Irrigation: Efficiently moving water for irrigation purposes enhances crop production.

- Equipment Maintenance: Cleaning and maintaining machinery with high-pressure water can prevent breakdowns and extend equipment life.

- Fluid Management: Quickly transferring pesticides or fertilizers ensures timely applications.

3. Structural Engineering

The structural engineering sector can greatly benefit from the adoption of compressed air water pumps:

- Site Cleanup: Fast and efficient water removal from construction sites prevents delays caused by heavy rain.

- Testing Structures: Compressed air water pumps can be used to perform hydrostatic pressure tests on various structural components.

- Environmental Control: Managing water flow around construction sites to prevent erosion and maintain integrity.

Benefits of Implementing Compressed Air Water Pumps

The implementation of compressed air water pumps into your business can bring about several key advantages:

- Cost Savings: With reduced operating costs and improved fluid handling efficiency, businesses can save significantly over time.

- Increased Productivity: Faster operations lead to higher productivity levels, allowing businesses to take on more tasks and serve more clients.

- Enhanced Safety: The reduced risk of electrical hazards and improved reliability contribute to a safer workplace.

- Less Maintenance: Compared to traditional electric pumps, compressed air pumps often require less frequent maintenance and repairs.

Choosing the Right Compressed Air Water Pump

Selecting the right compressed air water pump involves understanding your specific needs. Consider the following factors:

- Flow Rate: Determine the volume of fluid you need to move to ensure the pump can meet those demands.

- Pressure Requirements: Make sure the pump can operate effectively under the required pressure for your tasks.

- Construction Material: Ensure the pump is made from durable materials suitable for your environment, especially if exposed to harsh conditions.

- Portability: If your applications require movement from one site to another, consider lightweight and portable models.

Maintenance Tips for Compressed Air Water Pumps

To ensure longevity and optimal performance of your compressed air water pump, regular maintenance is crucial. Here are some practical maintenance tips:

- Regular Inspections: Check for leaks or any signs of wear and tear on a routine basis.

- Cleaning: Keep the pump clean and free of debris to ensure smooth operation.

- Lubrication: Ensure all moving parts are properly lubricated to prevent wear and tear.

- Air Filter Maintenance: Regularly check and clean air filters to maintain the quality of compressed air entering the pump.

Conclusion

The integration of compressed air water pumps into the operations of businesses in the auto repair, farm equipment repair, and structural engineering sectors is a significant step towards enhancing efficiency and productivity. Companies like Michael Smith Engineers demonstrate how these tools can lead to remarkable advancements in operational workflows. By understanding the applications, benefits, and maintenance of these pumps, businesses can unlock new levels of performance and ensure their future success.

If you are looking to improve productivity and efficiency in your industrial operations, consider investing in a high-quality compressed air water pump today.